3D printing during a pandemic

As a disclaimer, this story contains content surrounding Covid-19. I completely understand that not everyone is in a place to read about this very real issue.

I recently started working in the software development and consulting industry, so recently in fact that I’ve spent more time working from home in our current situation than I have spent at the offices. But before that, I was in the process of becoming a professional student of chemical engineering and the topic of my Master’s thesis was focused on making specialised materials for 3D printing. Yes, that's right, I came in to “work” on campus every day to drink coffee and play around with 3D printers.

While there is a little bit more to it than that, suffice it to say that I enjoyed 3D printing enough to change my topic 1 year deep into a 2 year degree. And by the way, we are now in year 3, and I don’t know if “enjoy” is a suitable term I can use any more. It has become a labour of love to continue my research, and while I still use my printer as a trinket collector, I haven’t printed anything meaningless since March 16th. Pause for dramatic effect while I divert away from the story to explain a little about 3D printers.

Tangent number 1.

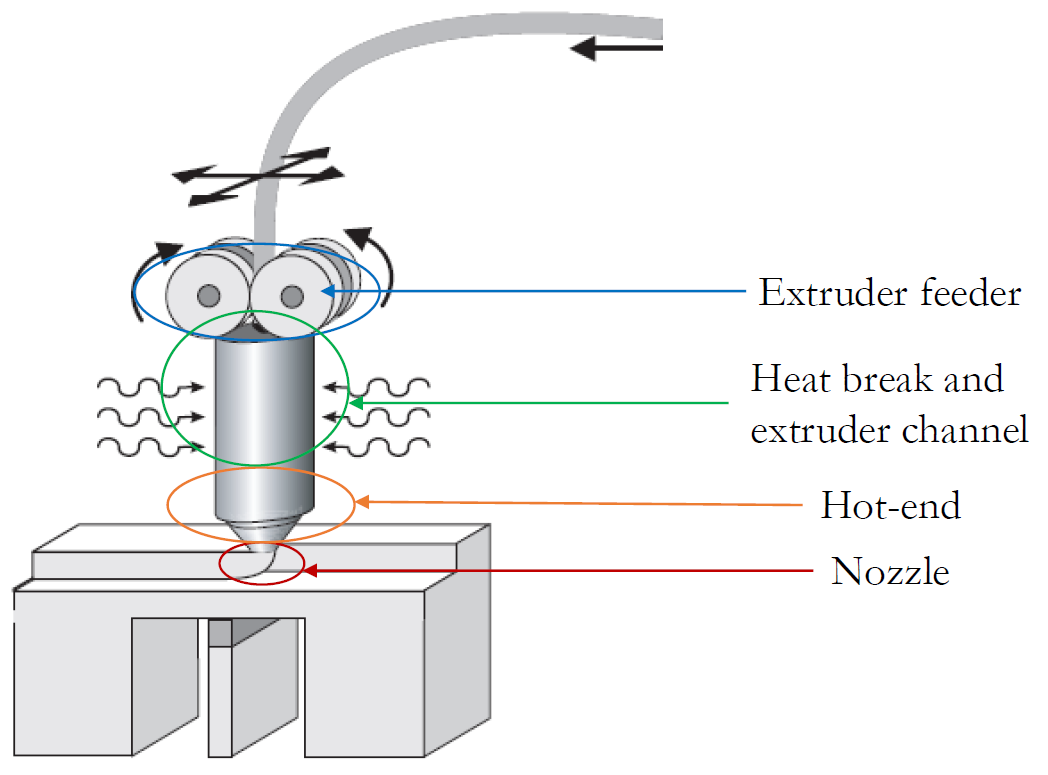

3D printing is a very loose term, and it actually covers a huge array of processing and manufacturing techniques ranging from hobbyist and prototyping machines that use plastic strand or resin, to metal laser-melting machines that make parts for aeroplanes and BMWs, but the one that I’d like to talk about is known as fused deposition modelling (FDM, the patented name) or as fused filament fabrication (FFF, the fffreely available name). In the simplest terms, FDM is a process of melting some plastic stock material and then placing it down in specific patterns, one layer at a time, until the final print takes the wanted shape. Here’s a slightly more complicated version, but in picture format.

Tangent number 2.

FDM (and 3D printing in general) produces parts that can be stronger* and use less* material than a conventionally produced part thanks to the nature of additive manufacturing, but both of these have some hidden terms and conditions. I used another term for 3D printing there (Additive Manufacturing, AM). In its simplest definition, AM is manufacturing a part “from nothing”. No, you can’t make something from nothing but the manufacturing is done in such a way as to add to the part until it is finished, like building a wall out of bricks and cement in an empty area instead of carving a wall from a giant rock.

Additive manufacturing is the newest kid on the block when industrial manufacturing for mass consumer-production is concerned. Its more mature family members are Subtractive and Formative manfacturing. Subtractive manufacturing is, you guessed it, the removal of material from a stock object until your desired part is realised. Milling, turning, carving, grinding, cutting, tapping, threading, and a couple hundred more processes are all examples of subtractive techniques. Subtractive manufacturing is the old-reliable, and yes there is cutting edge tech involved, but the processes are established and well known. The disadvantages of throwing away anywhere from 20% to 90% of your stock material has been accepted long ago and its only the arrival of the new kid on the block that has started to make the masses reconsider. The digital-age comparison to a 3D printer is a CNC milling machine or lathe, and there is generally no limit to the materials that can be used for manufacturing but the designs are limited by the geometries of the subtractive cutting tools (#foreshadowing, see the images below).

Formative Manufacturing is the middle child here, we don’t start from nothing and end up with the designed part, nor do we start with a big hunk of material and carve our way through to our designed part. Formative manufacturing is in a sweet spot where (by definition, not practice) all the material that we start with is converted from one shape into our desired shape. This is usually associated with materials that can deform or melt and cool. Pottery, glass blowing, metal casting, plastic moulding/forming, fibre-glass and ply-wood layering are the examples for this class of techniques. LEGO is a fantastic product example, and formative manufacturing really shines because of the speed of manufacturing we can achieve. The techniques are often limited by the shape of the shells we use to form these products and the cost of making these moulds and cavities are the biggest disadvantage by far. There is no easy tech comparison to a 3D printer here, the processes are not similar at all.

Was that an unannouced tangent? Lets go back to additive stuff again, please and thank you. So what is so great about all these different forms of additive manufacturing? This concept allows for part manufacture without cost of creating the mold or jig needed to make the part, but at the expense of time to manufacture. This is a huge advantage if you are a maker of custom pieces in small volumes, not so much if you are a major manufacturer of mass goods. But the real strength here is that the manufacturing technique allows for design that can use and abuse the power of geometry in difficult to reach areas without wasting material, and can also allow for some algorithmic design that completely ignores what you think a strong shape would look like and instead calculates the optimal shape that results in the best possible strength of the part.

Truly deviating from the topic, here’s an impossible to mill/carve chess piece, and a wheelchair frame design cycle that should boggle the mind. The frames are produced with a different form of 3D printing (because metal) so technically this example is cheating, but I think this design is cooler than a few optimised shelf brackets.

Lets now stop staring at the all stars of 3D printing and look closer to home. FDM was the topic, and because of how it works, stronger doesn’t always mean stronger. Before I showed you pretty pictures of organically designed wheelchairs, I mentioned FDM can produce stronger parts for less material than subtractive can. This statement is only valid in a max of 2 out of 3 dimensions because of the layer-by-layer effect. Very quickly, here’s some explanation for stronger* parts.

Tangent 2.5, okay fine… Tangent 3.

Instead of going into the maths behind inter-layer bonding, I will rather use a simple example. If you’re in the need for some chopped wood and you have some log rounds and an axe, do you strike the wood with the axe blade on exposed wood aiming along the grain, or do you strike the log’s exterior and cut against the grain? Along the grain is the correct answer because the strength between the grains is less than the strength inside a grain (if science is your thing, van der Waals forces and hydrogen bonding are weaker than covalent bonding of the cellulose long carbon chains). TL;DR: logs and 3D printed objects hold good strength in 2 dimensions but suck at being strong in the 3rd.

I’ve probably rambled away from my topic a little but hopefully I can wrap it all together now. The point I wanted to make is that 3D printing is fantastic set of processes with fantastic opportunities awaiting it as a technology in the future. But…Yes there is a but, for right now the only accessible printing technology is mostly used as a prototyping tool, or as a cosplay prop maker, a tabletop RPG miniature maker, or your DIY dream assistant in making that one of a kind thing to help you make some other thing. As it stands, 3D printing in the home is useful, mostly wasteful and decorative, but it wasn’t vital. All the tangents should be gone by now.

Dramatic pause over: COVID-19…

So March 16th was where I left off. A Monday I assumed would be like any other, except that through a small game of degrees of separation, I was potentially exposed to the virus that had recently found its way to South Africa. Luckily I was not infected, but between myself and my HR manager, it was decided that I should not step into the office if at all possible, and so my isolation and eventual quarantine-lockdown began.

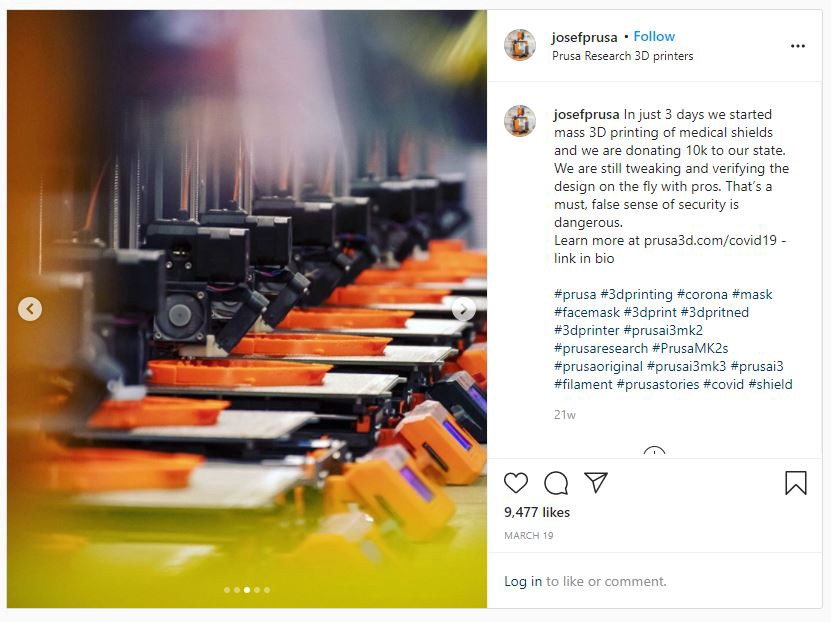

While browsing Instagram, I spotted a post by Josef Prusa, a pretty big name in the 3D printing world. They had converted their printer farm of over 400 printers into an emergency face shield manufacturing facility to print the rigid frame of a face-shield, and use their warehousing and distribution departments to send these frames and the rest of the required bits to their medical facilities in Prague.

Within a couple days this idea went global and my local 3D printing store sent out a call to action on their mail list. After some group politics, some red-tape and a few disagreements with some rather big names , 3DPSA and SA-fighting-covid was born.

This non-profit organisation consisted of a few hundred local hobbyist 3D printer enthusiasts mass producing thousands of face shield frames from their homes and donating them to the COVID-19 task force, government medical staff and first responders that were in desperate need of PPE. Through some company donations of transparency plastic, plastic sheeting, rubber bands, 3D printing filament stock material and through sheer determination, 3DPSA has managed to print and deliver over 18 000 face shields to those in need.

I can’t claim to have been a huge contributor to this project, I have only had about 40 face shields collected from me and because of many other factors my printer is not really in production mode right now and I’m not in the mood for a house fire. Luckily, the community has some outstanding members and there are some that have printed several hundred face shields just by themselves. We have a leaderboard, therefore it’s a game/sport/challenge and all philanthropic ambition is out the window. Obviously that is not true, the group has gone above and beyond any expectation of any hobbyist society to make sure the people on the front-lines of this pandemic had some PPE in a time when there was basically nothing available.

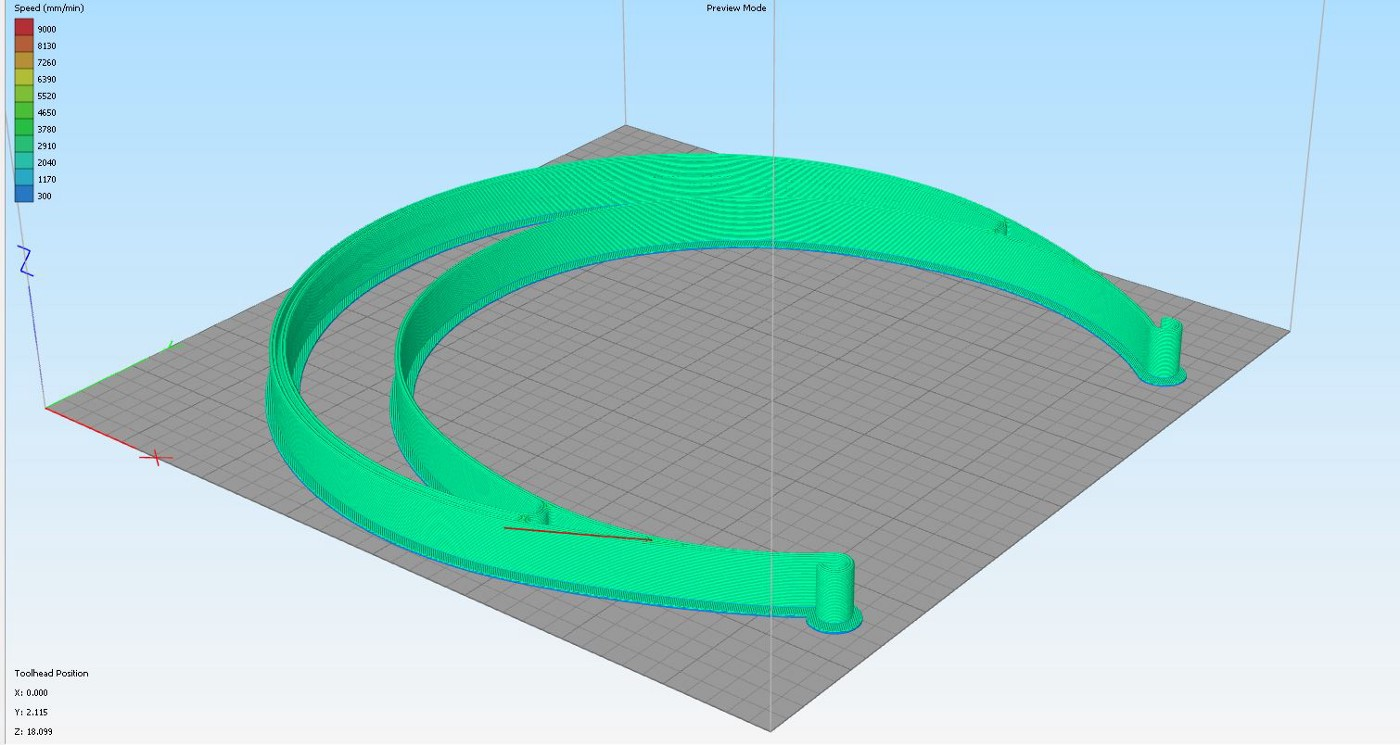

This global movement sparked from hobbyist passion and determination, and there was some sheer dumb luck involved as well. There are other 3D projects on the go around the world to make respirator ducting, sleeves, braces, rigid face masks with filter template cutouts and a host of other parts, but none of them spread like the wild fire that was the face shield. The reason for this is quite simple, the face shield is a perfect part for FDM manufacture. Here is a picture of the face shield frame in some 3D printing software, which exaggerates the layer appearance. For the record, this is one of 3DPSA’s designs, and it is quite genius in it’s application. There is a small gap in the walls of the front round thingy (top-left corner of the part in this image) that opens up when the part is stretched outward, where we add the clear plastic sheet of the shield, and then closes and clamps the sheet in place when relaxed or stretched inward.

Let’s try and make all those tangents worth it, shall we? I mentioned that FDM was slower than industrial formative techniques, but the face shield design is simple, so all FDM printers (regardless of build quality) should be able to replicate the design easily and quickly. The crowd-sourcing of this initiative and the simplicity of the design allowed for massive production volumes. I also mentioned the FDM strength deficiencies that can be present in many printed objects due to complexity in shape and the 2/3 directions of strength. The layers of the design are identical, so there is less chance of printing failure due to complex movements and printing over empty space. But most importantly, the 2-axis printing direction matches perfectly to the planes of stress that the part will experience while it is used. This means that the design completely eliminates the weaknesses that FDM brought to the table, and the nature of additive manufacturing allowed for some very cool design features like 3DPSA’s crimp mechanism.

So after several tangents, here we are. 3D printing can, and probably will be ground-breaking technology. One day. For now, I still think hobbyist 3D printers are very limited in their use, but every now and then there comes an opportunity for FDM to shine as a brilliant solution. For clarity, my Masters is definitely not one of these shining moments. But providing some relief, providing some purpose and motivation to many people that were in an emotional tail spin, and allowing a group of people to come together in solidarity to support the community, definitely is.

For more information, you can find SA-fighting-covid at https://www.southafricafightingcovid.com/